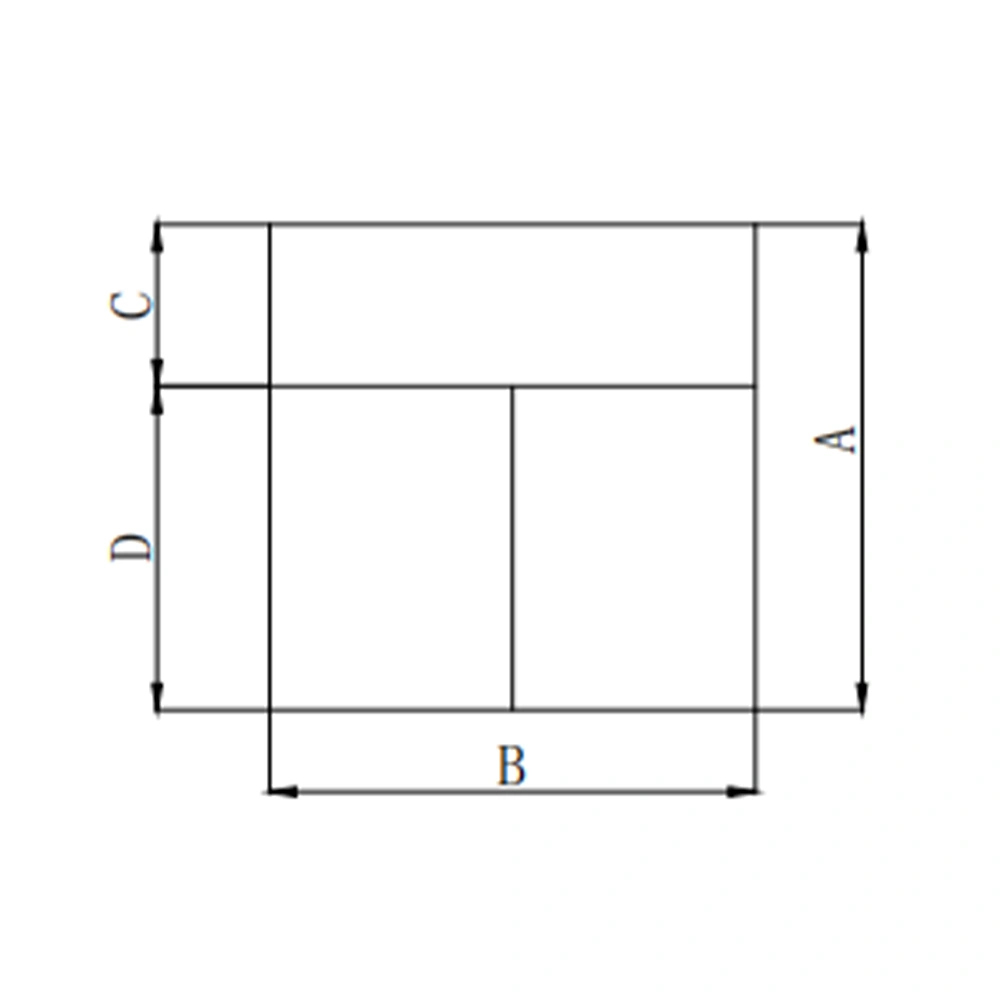

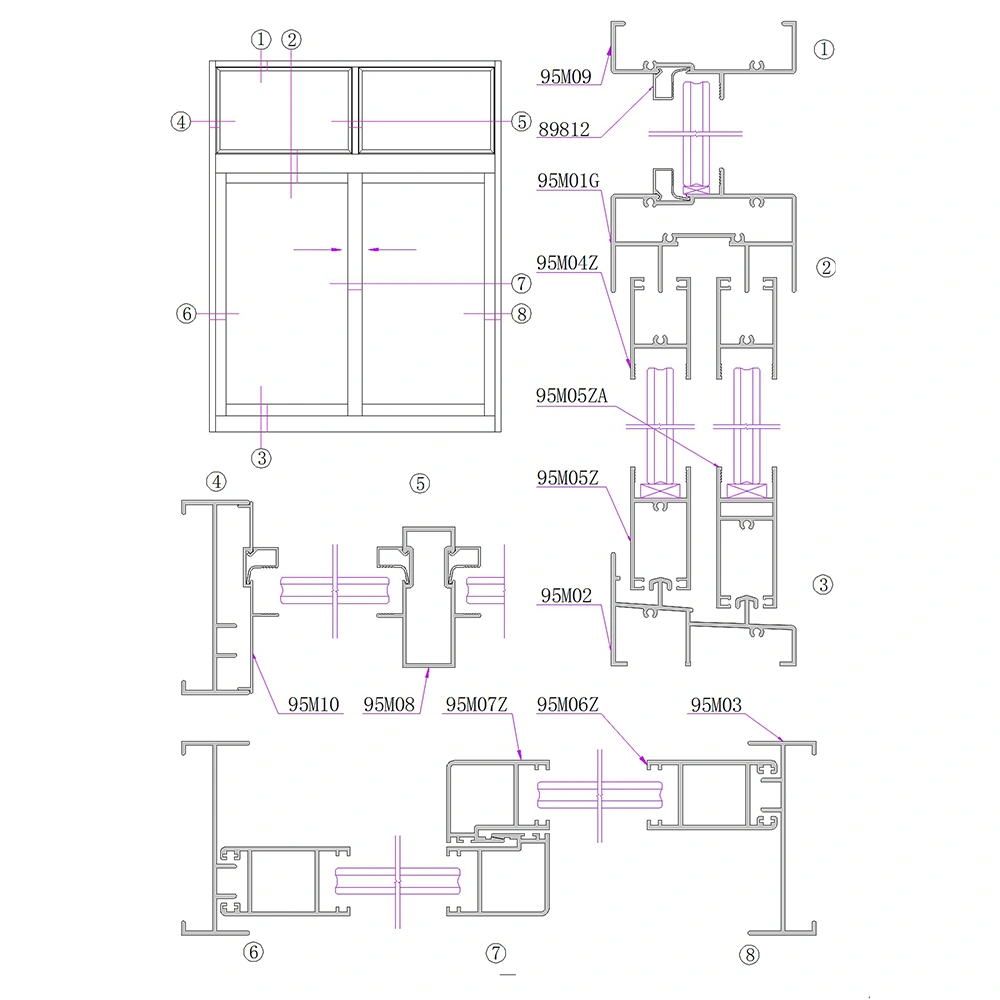

1800mm × 1200mm Standard Door

Material Thickness 1.8mm

A=1800mm B=1200mm C=600mm D=1200mm

| Name | Model | Formula | Length (mm) |

Weight (kg/m) |

Quantity | Sum (kg) |

|---|---|---|---|---|---|---|

| Side Seal | 95M03 | A | 1800 | 0.920 | 2 | 3.312 |

| Fixed Upper Sash Rail | 95M09 | B-35 | 1165 | 0.880 | 1 | 1.025 |

| Fixed Upper Sliding Rail | 95M01G | B-35 | 1165 | 1.794 | 1 | 2.090 |

| Lower Sliding Rail | 95M02 | B-35 | 1165 | 1.363 | 1 | 1.588 |

| Clamping Plate | 95M10 | C-26 | 574 | 0.692 | 2 | 0.794 |

| Sash Stile | 95M06Z | D-71.8 | 1128.2 | 1.052 | 2 | 2.210 |

| Sash Stile | 95M07Z | D-62.8 | 1137.2 | 0.907 | 2 | 2.227 |

| Upper Frame Rail | 95M04Z | B/2-76.6 | 523.4 | 0.727 | 2 | 0.736 |

| Lower Frame Rail | 95M05Z | B/2-76.6 | 523.4 | 0.831 | 2 | 0.420 |

| H-Bead | 89812 | B-70.8 | 1129.2 | 0.130 | 2 | 0.294 |

| V-Bead | 89812 | C-26 | 574 | 0.130 | 2 | 0.149 |

| Total Weight | 1.8m × 1.2m =2.16m2 | 15.374 | ||||

| Average Weight | (kg/m2) | 15.374/2.16=7.12 | ||||

Color consistency is critical for architectural projects.

We control color difference through fully automated anodizing, electrophoresis, and powder coating lines, with strict batch-by-batch production management.

Profiles for the same project are produced in the same batch to ensure uniform surface appearance.

Yes. Wall thickness can be customized according to project requirements.

For export markets, we generally recommend 1.3–1.6 mm for standard doors and windows, and 2.0–3.0 mm for large curtain wall or high-rise applications to ensure structural strength and safety.

A system window is not just an aluminum profile.

It is a complete solution, including aluminum profiles, hardware, sealing components, and defined processing standards.

This system-based approach ensures reliable performance in air tightness, water tightness, wind resistance, and durability.

We mainly offer three categories: construction profiles (for doors, windows, curtain walls), industrial profiles (for automation equipment, radiators), and decorative profiles (for furniture, display racks). We provide common alloy grades like 6061, 6063, and 6005, and can also produce according to international standards such as ASTM, DIN, and GB.

The MOQ for standard profiles is 500kg per model. For custom profiles, due to different mold costs, the MOQ is usually 1000-2000kg. If you need a small trial order, you can contact our sales team to discuss a special support plan.

Yes. You only need to provide 2D/3D drawings (with dimensions, tolerances, and surface treatment requirements marked) or physical samples. Our engineers will complete the feasibility assessment within 3 working days and provide the mold production cycle and quotation.

Mold making lead time: 7-10 working days for regular extrusion molds, and 12-15 working days for complex molds (such as multi-cavity or special-shaped ones). Mass production lead time: After mold confirmation, the mass production cycle is 10-15 working days (excluding surface treatment time).

Our products have passed the ISO9001 quality management system certification, and some products can meet the requirements of CE, SGS, ROHS and other certifications. We will provide third-party test reports (including mechanical properties, chemical composition, and dimensional tolerances) for each batch of goods before delivery. We also support re-inspection by customer-designated institutions.

Regular surface treatments include anodizing (salt spray resistance test ≥1000 hours), electrophoretic coating (≥1500 hours), powder coating (≥2000 hours), and fluorocarbon coating (≥4000 hours). We can recommend a suitable solution based on your application scenario (such as coastal areas or high-temperature environments).

We default to FOB delivery at major ports such as Qingdao, Shanghai, Guangzhou, and Shenzhen, and can also provide quotations based on terms like CIF and DDP. Logistics costs can be agreed upon according to trade terms. If you have a long-term cooperative freight forwarder, we can also coordinate with them.