Bolivia’s aluminum alloy windows and doors are primarily designed to meet the needs of local and South American markets while adhering to global standards for performance and style. They are mainly classified by opening methods, with some customized options integrating special functions and craftsmanship.

The common types are as follows:

Sliding Aluminum Alloy Windows & Doors

One of the best-selling types in Bolivia, featuring styles like three-track sliding windows (some with built-in insect screens) ideal for residential balconies, living rooms, and other spaces. Its key advantage lies in space-saving operation—sliding open without occupying extra area—while supporting large sash designs to maximize natural light and visual permeability. Crafted from Bolivia’s high-purity aluminum alloy, it resists deformation even under intense South American sunlight and adapts to diverse environments (coastal areas, urban centers, etc.). Widely used in residential buildings and small commercial facades.

Casement Windows & Doors

Popular in Bolivia for practical designs such as impact-resistant black frames, these feature a simple structure and excellent airtightness to withstand the region’s variable weather. Hinged for inward or outward opening, they offer high ventilation efficiency. Paired with double-glazed insulated glass, they enhance soundproofing and thermal insulation. The high-strength aluminum alloy frame, combined with specialized hardware, ensures superior security—making them suitable for bedrooms, studies, and other spaces requiring tranquility and safety. Also commonly used in mid-to-high-end residences and commercial offices.

Tilt & Turn Windows

A practical and safe option favored in Bolivia’s villas, high-end apartments, and luxury properties. It offers two opening modes: inward casement for maximum ventilation, and inward tilt for air circulation while preventing rainwater infiltration and child falls. Some models are equipped with premium hardware (e.g., Germany’s Roto) and leverage Bolivia’s aluminum alloy’s corrosion resistance for long service life. Adaptable to diverse living environments, from mountainous regions to urban areas.

Explosion-Proof Aluminum Alloy Windows Tailored for high-security scenarios such as commercial complexes, luxury security buildings, and critical infrastructure. Constructed with thickened aluminum alloy frames and impact-resistant glass, they can withstand external impacts, storms, and extreme conditions. The high-strength frame prevents glass shattering and detachment, forming a robust safety barrier. The aluminum alloy material also eliminates concerns about rust and corrosion during long-term use.

Custom-Styled Aluminum Alloy Windows & Doors

Customized to match various architectural aesthetics through specialized craftsmanship. For example:

Wood grain transfer technology mimics oak, walnut, or teak textures, suitable for rustic-style buildings.

Anodized (champagne gold, matte black) or sandblasted finishes cater to modern minimalist or luxury residential/commercial spaces.

Additionally, custom-sized aluminum alloy doors are available for large-scale projects, with dimensions and opening methods tailored to engineering requirements. Processes like electrophoresis and sandblasting ensure both aesthetic appeal and durability.

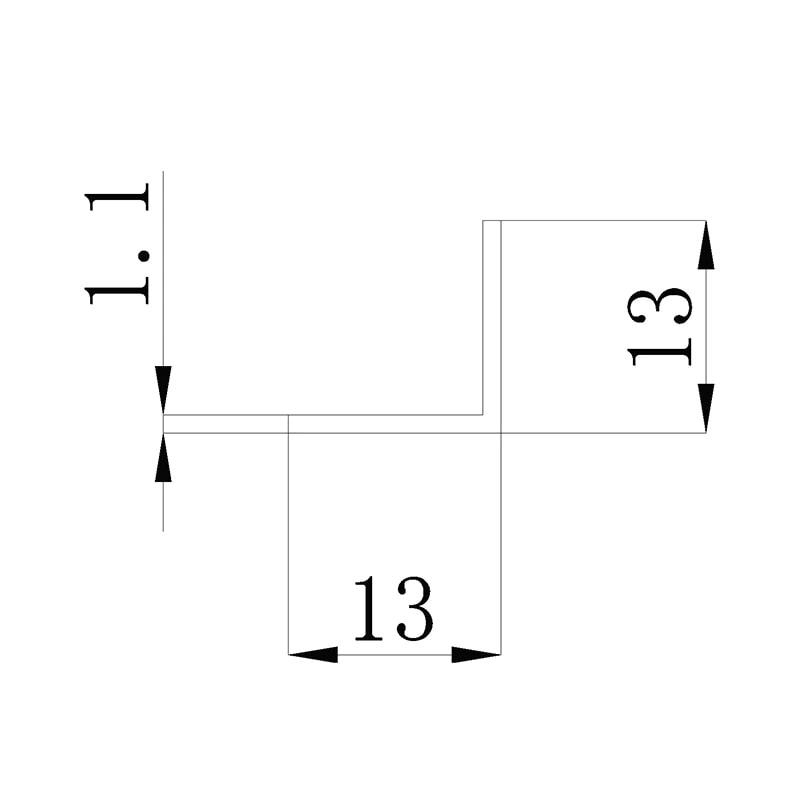

| Model No. | Thickness(mm) | Weight(kg/m) |

|---|---|---|

| KDB1010 | 1.1 | 0.100 |

| KDB1018 | 0.8 | 0.184 |

| KDB1120 | 1.0 | 0.200 |

| KDB12070 | 0.7 | 0.510 |

| KDB13130 | 1.3 | 0.149 |

| KDB137 | 1.1 | 0.074 |

| KDB1422 | 1.3 | 0.220 |

| KDB1508 | 1.1 | 0.086 |

| KDB1513 | 1.0 | 0.130 |

| KDB1515 | 1.0 | 0.150 |

| KDB16130 | 1.3 | 0.154 |

| KDB1709 | 1.1 | 0.098 |

| KDB1713 | 1.0 | 0.130 |

| KDB1741 | 1.0 | 0.410 |

| KDB2016 | 1.1 | 0.160 |

| KDB21110 | 1.1 | 0.240 |

| KDB2112 | 1.0 | 0.129 |

| KDB2250 | 2.5 | 0.320 |

| KDB23120 | 1.2 | 0.250 |

| KDB2332 | 2.5 | 0.320 |

| KDB2490 | 0.9 | 0.130 |

| KDB2516 | 1.2 | 0.160 |

| KDB2526 | 1.0 | 0.400 |

| KDB2735 | 1.0 | 0.350 |

| KDB3031 | 1.0 | 0.310 |

| KDB32100 | 1.0 | 0.258 |

| KDB38100 | 1.1 | 0.490 |

| KDB38110 | 1.1 | 0.360 |

| KDB3836 | 1.0 | 0.360 |

| KDB3846 | 1.0 | 0.460 |

| KDB4042 | 1.0 | 0.422 |

| KDB43100 | 1.0 | 0.485 |

| KDB4437 | 1.0 | 0.370 |

| KDB4439 | 1.0 | 0.390 |

| KDB4440 | 1.0 | 0.400 |

| KDB4447 | 1.0 | 0.474 |

| KDB5040 | 1.0 | 0.400 |

| KDB5144 | 1.0 | 0.440 |

| KDB5148 | 1.1 | 0.480 |

| KDB60110 | 1.1 | 0.420 |

| KDB60120 | 1.2 | 0.568 |

| KDB60270 | 2.7 | 0.930 |

| KDB6032 | 1.1 | 0.320 |

| KDB6037 | 1.0 | 0.370 |

| KDB6048 | 1.0 | 0.480 |

| KDB6061 | 1.0 | 0.610 |

| KDB6062 | 1.3 | 0.620 |

| KDB6139 | 0.9 | 0.390 |

| KDB6149 | 1.0 | 0.490 |

| KDB6550 | 1.0 | 0.503 |

| KDB6659 | 1.0 | 0.590 |

| KDB6660 | 1.0 | 0.600 |

| KDB6663 | 1.0 | 0.630 |

| KDB6954 | 1.0 | 0.540 |

| KDB7045 | 1.0 | 0.450 |

| KDB78130 | 1.3 | 0.800 |

| KDB7829 | 1.0 | 0.293 |

| KDB8077 | 1.2 | 0.770 |

| KDB9270 | 0.7 | 0.410 |

Color consistency is critical for architectural projects.

We control color difference through fully automated anodizing, electrophoresis, and powder coating lines, with strict batch-by-batch production management.

Profiles for the same project are produced in the same batch to ensure uniform surface appearance.

Yes. Wall thickness can be customized according to project requirements.

For export markets, we generally recommend 1.3–1.6 mm for standard doors and windows, and 2.0–3.0 mm for large curtain wall or high-rise applications to ensure structural strength and safety.

A system window is not just an aluminum profile.

It is a complete solution, including aluminum profiles, hardware, sealing components, and defined processing standards.

This system-based approach ensures reliable performance in air tightness, water tightness, wind resistance, and durability.

We mainly offer three categories: construction profiles (for doors, windows, curtain walls), industrial profiles (for automation equipment, radiators), and decorative profiles (for furniture, display racks). We provide common alloy grades like 6061, 6063, and 6005, and can also produce according to international standards such as ASTM, DIN, and GB.

The MOQ for standard profiles is 500kg per model. For custom profiles, due to different mold costs, the MOQ is usually 1000-2000kg. If you need a small trial order, you can contact our sales team to discuss a special support plan.

Yes. You only need to provide 2D/3D drawings (with dimensions, tolerances, and surface treatment requirements marked) or physical samples. Our engineers will complete the feasibility assessment within 3 working days and provide the mold production cycle and quotation.

Mold making lead time: 7-10 working days for regular extrusion molds, and 12-15 working days for complex molds (such as multi-cavity or special-shaped ones). Mass production lead time: After mold confirmation, the mass production cycle is 10-15 working days (excluding surface treatment time).

Our products have passed the ISO9001 quality management system certification, and some products can meet the requirements of CE, SGS, ROHS and other certifications. We will provide third-party test reports (including mechanical properties, chemical composition, and dimensional tolerances) for each batch of goods before delivery. We also support re-inspection by customer-designated institutions.

Regular surface treatments include anodizing (salt spray resistance test ≥1000 hours), electrophoretic coating (≥1500 hours), powder coating (≥2000 hours), and fluorocarbon coating (≥4000 hours). We can recommend a suitable solution based on your application scenario (such as coastal areas or high-temperature environments).

We default to FOB delivery at major ports such as Qingdao, Shanghai, Guangzhou, and Shenzhen, and can also provide quotations based on terms like CIF and DDP. Logistics costs can be agreed upon according to trade terms. If you have a long-term cooperative freight forwarder, we can also coordinate with them.